plug flow reactor example problem

Continuous Isothermal Plug Flow Tubular Reactor. PlotV_ssCa_ss k-- linewidth 2 plotVCend r last solution of transient part legend Steady state solution transient solution at t100.

Matlab In Chemical Engineering At Cmu

K C 100 dm 3 mol.

. Y A 02 y B 05 y C 03 C is an inert. Steady-state mass balance on cells X L X o exp-k d 1k dlnX o X L 15hrln10 6103 14 hr. The same example problem has been worked in Aspen and MatlabA completed case has been prebuilt and is located in the file PlugFlowExhsc in the HartsookHysysSAMP403 directory.

The PFR model is used to predict the behavior of chemical reactors of such design so that key reactor variables such as the dimensions of the reactor can be estimated. The reactor may be either isothermal or adiabatic or may have a. A 2B 2D r A -25C A 05 C B mol L-1 min-1.

Example 11-3 Adiabatic Liquid-Phase Isomerization of Normal Butane. The volumetric flow rate of the feed is 50 Lmin. The reaction is gas-phase in an isothermal PFR and is at 50 atm pressure and 55C.

Derive an equation relating the reactor volume to the entering and exiting concentrations of A the rate constant k and the volumetric flow rate 0. Steady State Two types of problems. A brief overview of plug flow reactors their properties equations and uses.

This example will take you through the entire process of setting up multiple reactions and creating a plug flow reactor in HYSYS as shown in the picture above. The plug flow reactors describe above may be described as closed in that they are enclosed in a pipe-like geometry. F A0 5 molmin.

Water at a controlled temperature is circulated through the tank to maintain constant reactant temperature. Demonstrates the use of reactor models through an example problem on the production of ethyl acetate in Aspen Plus. A plug flow reactor PFR is a type of chemical reactor where the influent is pumped.

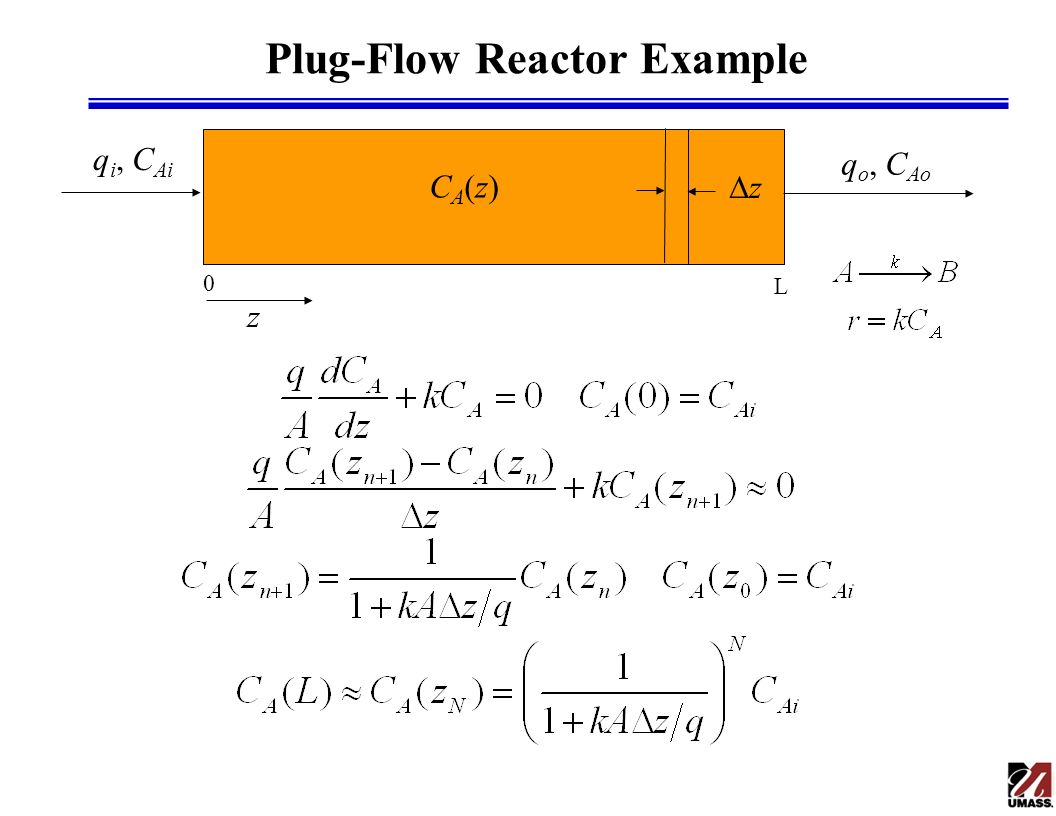

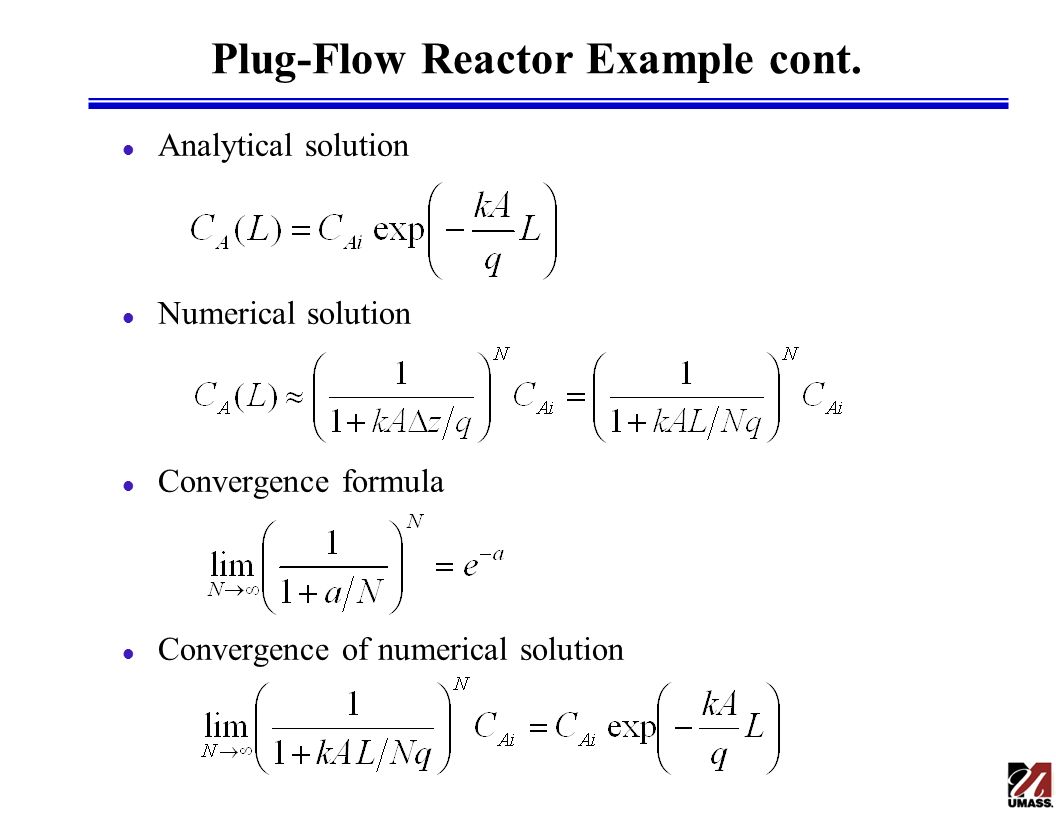

Plug Flow Reactor Example. The plug flow model has many practical applications. Chemical Engineering questions and answers.

V_ss Ca_ss ode45pfrvspan2. For the optimum temperature progression in a plug flow reactor in Example 94 CA0 4 molliter FA0 1000 mol Amin XA 08 T min 5C Tmax 95C and feed and product both at 25C how much heating and cooling would be needed a for the feed stream. Hold all vspan 0 20.

Determine the reactor volume V necessary to reduce the exiting concentra- tion to 10 of the entering concentration ie CA 01Cao when the volumet- ric flow rate 2 is 10 dmmin ie litersmin and the specific reaction rate k. Pictured below is a plug flow reactor in the form of a tube wrapped around an acrylic mold which is encased in a tank. Made by faculty at Lafayette College and.

It can be shown2 that the absence of axial mixing allows the achievable reactant conversion to be maximized. Determine X e for a PFR with no pressure drop P P 0. Some examples of reactors include lakes rivers and sedimentation tanks.

In the case of tube flow the accepted ideal is the plug-flow reactor in which it is assumed that there is no mixing in the axial flow direction but perfect mixing in the directions transverse to this. The volumetric flow rate of the feed is 50 Lmin. Formation rate of R is empirically correlated by the equation B A A B R C C C C r 1 05 1 rR in molLh CA and CB in molL The plug flow reactor is fed with a flow rate of 200 kmol A h and the feeding is 50 A and 50 B.

The plug flow model assumes there is no boundary layer adjacent to the inner wall of the pipe. Fluid going through a PFR may be modeled as flowing through the. Essentially no back mixing is assumed with.

K 2 dm 3 mol-min. C A0 02 moldm 3. The reaction is gas-phase in an isothermal PFR and is at 50 atm pressure and 55C.

Made by faculty at the University of Colorado Boulder Department of Chemical. We can solve the steady state plug flow reactor problem like this. Another sort of plug flow reactor could be described as open.

Reactor volume and flow path length L such that X L 10 3 cells100 ml 2. Given desired production rate conversion and kinetics and other parameters determine the required reactor size heat duty and temperature profile. Develop equations to determine plug flow reactor size for 50 conversion of reactant A.

Plug flow reactors are unique in the sense that operation in parallel or series give the same conversion if the space time is held constant. This implies for example that if a 20-m reactor of fixed diameter is required to achieve a given conversion the same conversion and capacity can be achieved by running. The reaction takes place at 3 atm and 150C.

Kayode Coker in Ludwigs Applied Process Design for Chemical and Petrochemical Plants Fourth Edition 2015. Function dCdV pfrVC dCdV 1vo-kC2. A completed case has been pre.

NONISOTHERMAL OPERATION OF IDEAL REACTORS Plug Flow Reactor T o F jo Q o T F j T mQ mT T o T m mo Assumptions. For example the reactor may consist of a tube placed in a bath a tube in a jacket or a. Chemical biological and physical processes take place in reactors.

The degree of mixing and residence time in reactors affect the degree of completion of reactions within the reactor. One example is in the design of chemical reactors. Plug Flow Reactor Example This example will take you through the entire process of setting up multiple reactions and creating a plug flow reactor in HYSYS as shown in the picture above.

A shower curtain the walls of a bathtub or a canyon wall seep all. Given that the system is gas phase and isothermal determine the reactor volume when X 08 X e. This elementary reversible reaction is to be carried out adiabatically in the liquid phase under high pressure using a liquid catalyst which gives a specific reaction rate of 311 h -1 at 360 K.

In plug flow the velocity of the fluid is assumed to be constant across any cross-section of the pipe perpendicular to the axis of the pipe. A 2B 2D r A -25C A 05 C B mol L-1 min-1. Their construction is varied.

Both homogeneous gas-phase and heterogenous surface reactions can be accommodated. Gas phase reaction 4A B R S is performed in a plug flow reactor. Normal butane C 4 H 10 is to be isomerized to isobutane in a plug-flow reactor.

Chlorine concentration which must be added to insure that there is detectable chlorine at PFR exit detection level C L 005 mgL 1. Plug Flow Reactor Simulator abstractNote PLUG is a computer program that solves the coupled steady state continuity momentum energy and species balance equations for a plug flow reactor. The plug flow reactor model is a model used to describe chemical reactions in continuous flowing systems of cylindrical geometry.

Plug Flow Reactors Plug flow or tubular reactors consist of a hollow pipe or tube through which reactants flow. Y A 02 y B 05 y C 03 C is an inert. The same example problem has been worked in Aspen and Matlab.

IIIC3ai Plug flow reactors. B in the. Develop equations to determine plug flow reactor size for 50 conversion of reactant A.

The plug flow tubular reactor is a heat exchanger in which the reaction occurs in the tubes.

1 4 Continuous Flow Reactors Mole Balances In Chemical Reaction Engineering Informit

Plug Flow Reactor Model A Plug Flow Reactor Pfr Model Is Used By Justin Mitchell Medium

Isothermal Plug Flow Reactor Part 1 Youtube

Plug Flow Reactor Pfr Sizing And Conversion Example Youtube

Elements Of Chemical Reaction Engineering

Variable Density Reaction In A Pfr Youtube

Selected Differential System Examples From Lectures Ppt Video Online Download

6 7 Ode And Excel Model Of An Adiabatic Pfr Engineering Libretexts

Plug Flow Reactor Overview Youtube

Plug Flow Reactor An Overview Sciencedirect Topics

Elements Of Chemical Reaction Engineering

Thoughts On Problem Solving Pfr Cstr Example

Selected Differential System Examples From Lectures Ppt Video Online Download

Sizing A Plug Flow Reactor Pfr Youtube